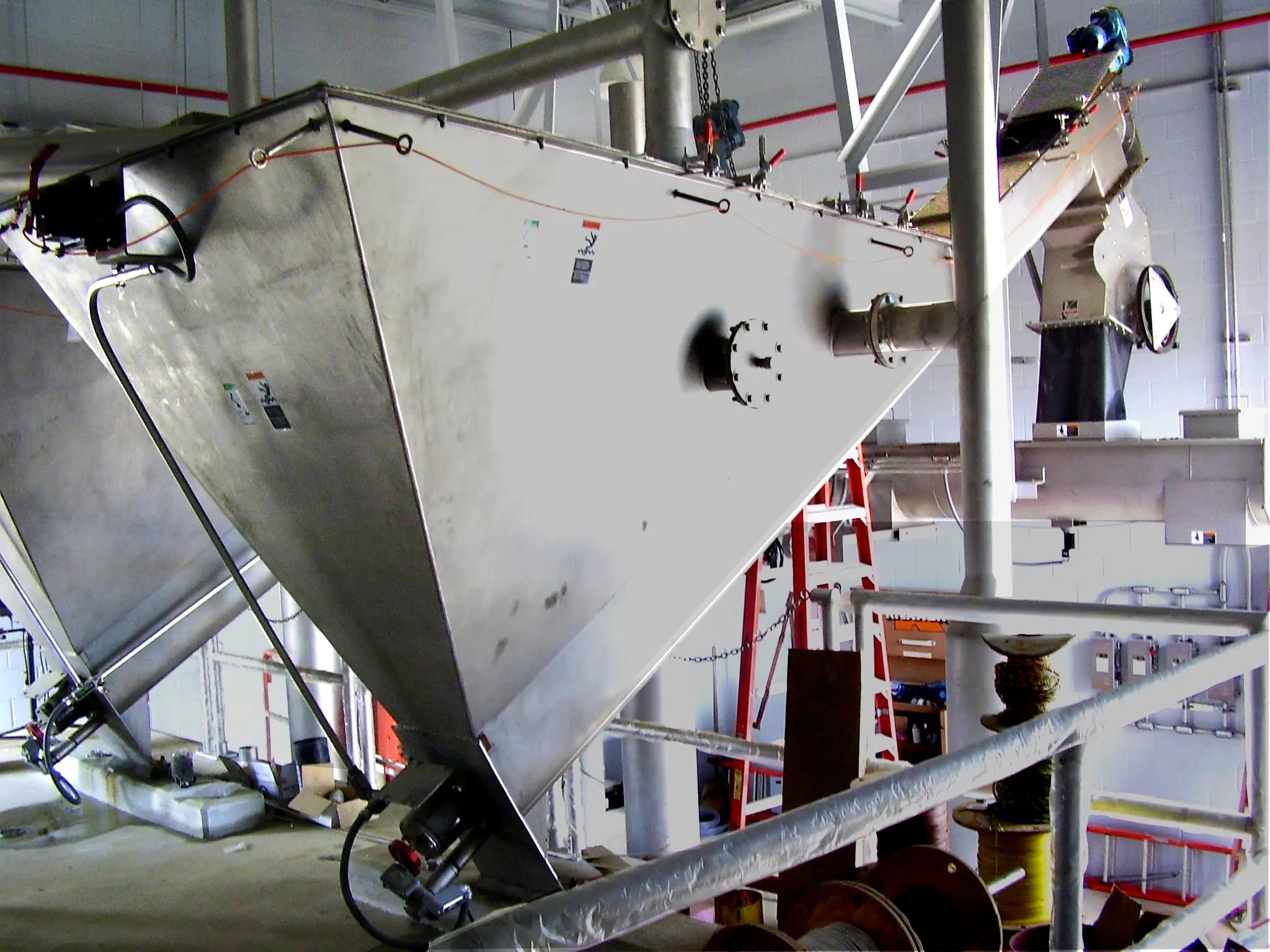

HFR (High Flow Rate) Grit Washer

The high performance of the HFR Grit Washer is achieved by immediately redirecting the inlet stream to create predictable flow patterns which promote rapid separation and settling of solids. The heavy inorganic grit is forced to settle and in turn be conveyed by the screw discharge while lighter organics are carried over the front discharge weir to be returned to the treatment process flow. Dual adjustable weirs are standard.

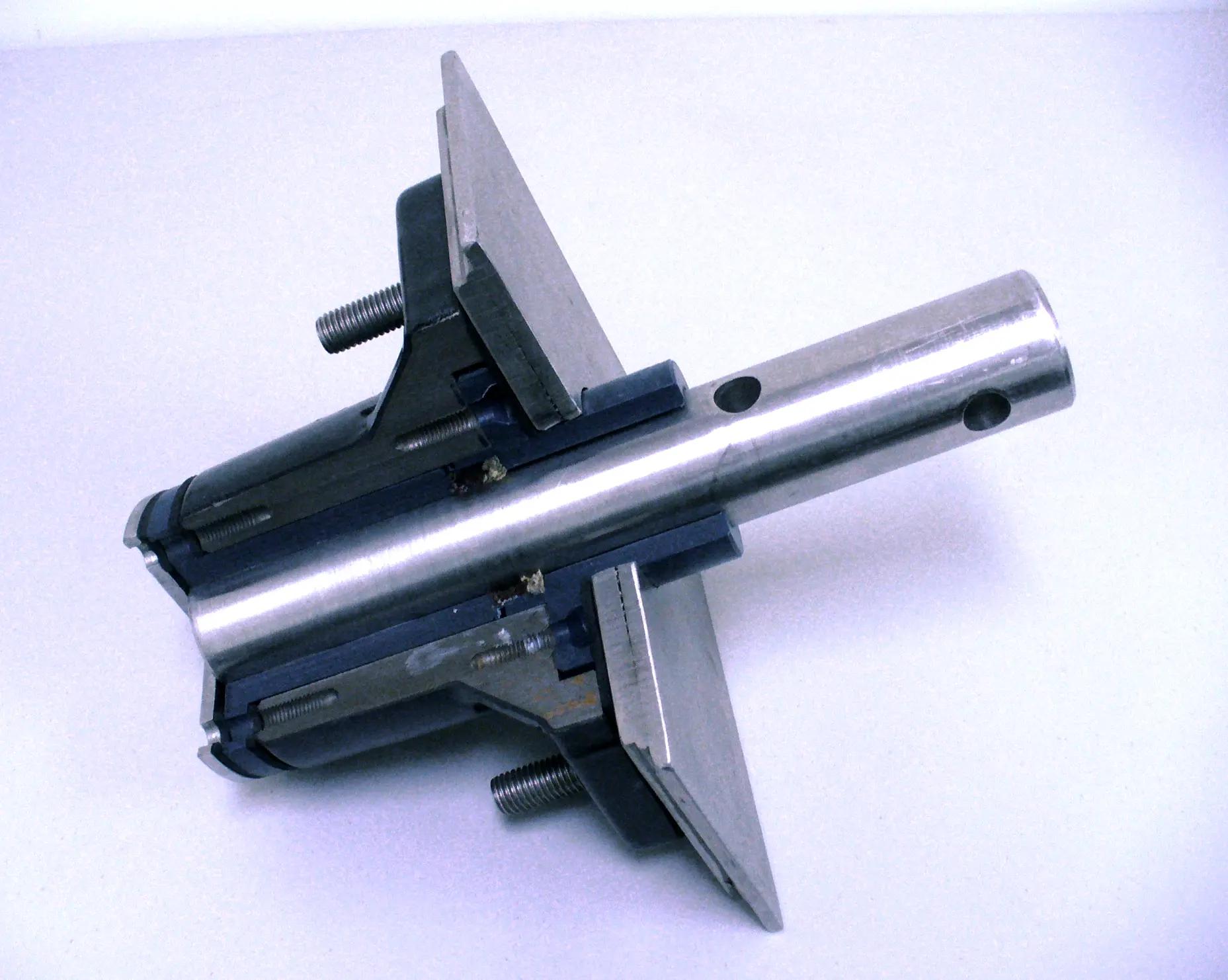

The heart of the grit washer system is the specially designed interior baffle assembly. The compact flow redirecting inlet distribution assembly, diffusion and discharge plates make up the baffle assembly and are fully removable from the unit for ease of maintenance and access to the screw.

Features

- 95% removal efficiency of 100 mesh grit particles (150 Micron)

- Non-lube “Posi-Seal” external bearing

- Variable speed drive to fine tune removal efficiency

- Dual adjustable weirs

- Eliminates need for cyclones

- Carbon steel and stainless steel construction

Applications

- Flows: to 400 GPM

- 95% removal efficiency of 65 to 150 mesh grit particles

- Grit removal capacity : 40 ft3/hr (65 mesh @ 6% feed)

Markets

- Municipal wastewater

- Industrial wastewater

- Pump stations

Parts

WSG & Solutions, Inc., is your OEM source for genuine Link-Belt® HFR (High Flow Rate) Grit Washer aftermarket parts and support. We stock common grit washer parts to ensure quick delivery and have the expertise and design records to provide rebuilds or retrofits to ensure the long-term operation of your system.

Contact us for the following common Link-Belt® HFR Grit Washer parts: lower bearings, screws, screw flight wearshoes, drive assemblies, electric components and ALL fabricated parts.